Update time : 2024-03-04 Publisher:Tongda

The raw materials for organic fertilizer processing are chicken manure, cow manure, pig manure, and sheep manure.

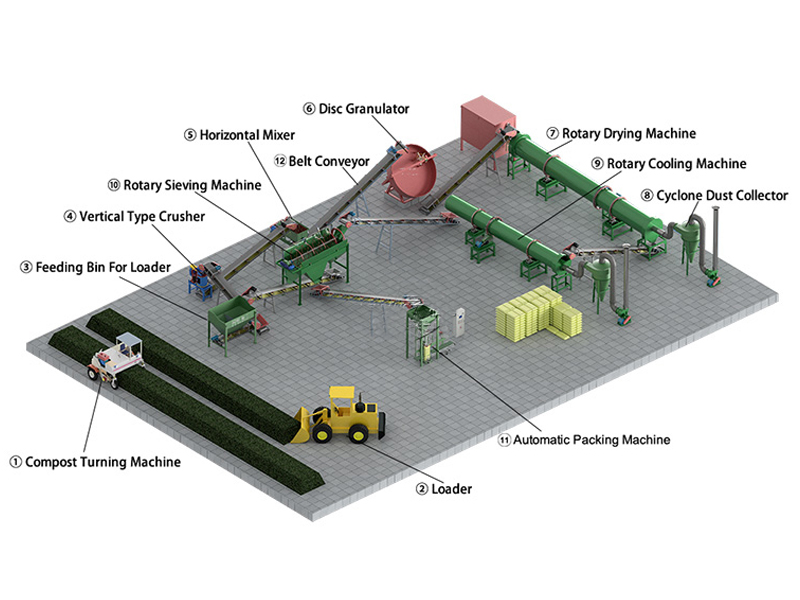

The production line equipment for organic fertilizer processing includes:Fermentation compost equipment, semi wet material crusher, mixer, granulator, dryer, cooler, screening machine, packaging machine, etc.

An annual output of 10000 tons of organic fertilizer can be achieved through the use of small-scale organic fertilizer production equipment.

Organic fertilizer processing equipment can be divided into high configuration and low configuration. Two different configurations of organic fertilizers have different qualities and can be chosen according to one's own needs. Purchasing raw materials refers to the procurement of livestock and poultry manure from farms or farmers for processing, as there is no raw material available for processing organic fertilizers such as cow manure, cow manure, or cow manure.

If you own a farm, you can save on the cost of purchasing livestock manure. Workers+water and electricity fees, wages of workers in different cities, and electricity fee charging standards are different, subject to local actual conditions.

Small scale cow manure organic fertilizer equipment, with an annual output of 100000 to 200000 tons of organic fertilizer, equipped with a complete set of equipment such as dehydrators, fermentation turners, crushers, screening machines, mixing mixers, granulators, dryers, coolers, screening machines, packaging machines, forklifts, etc.

The process of making cow manure organic fertilizer is as follows: first, use a dehydrator to control the water content of cow manure below 85%, then add straw powder, rice bran, corn flour and other auxiliary materials to control the water content between 50% and 70%; Sprinkle with special fermenting agent for cow manure. After thoroughly stirring with a mixer, use a shovel to shovel into the fermentation tank and use an organic fertilizer tippler to fully ferment and decompose; The conveyor belt between devices is used to transport particles to the crusher for crushing, and then to the organic fertilizer granulator for granulation. The produced particles have a high water content, which is then dried by a dryer and sent to a cooler to cool the particles and increase their strength. Then it is sent to the drum screen machine to screen out unqualified particles for secondary granulation. After passing the inspection, the finished product is packaged by the packaging machine.

see details +

see details +

see details +

see details +

Fermentation Compost Equipment >

Tel:+86 18538527111

Tel:+86 18538527111

E-mail:[email protected]

E-mail:[email protected]

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Privacy Policy Copyright © Henan Tongda Heavy Industry Science And Technology Co., Ltd.