Update time : 2024-08-14 Publisher:Tongda

The non drying granulator in the non drying organic fertilizer production line equipment is one of the main (bio) organic fertilizer production equipment currently produced by our company. It is a fertilizer machinery that our factory's scientific and technological personnel have researched, improved, and carefully manufactured based on years of production experience of advanced granulators at home and abroad. The machine has excellent technology, simple operation, and is designed with different models and ideal processing machinery for various organic fertilizer processing units.

Working principle: When the equipment is running, the material is squeezed down by the grinding wheel, then cut by the scraper, and then enters the secondary combination polishing and rolling process to form a ball. The non drying granulator has the advantages of high granulation rate, high particle strength, uniform roundness, low granulation moisture, and low drying energy consumption.

Its purpose and characteristics are as follows:

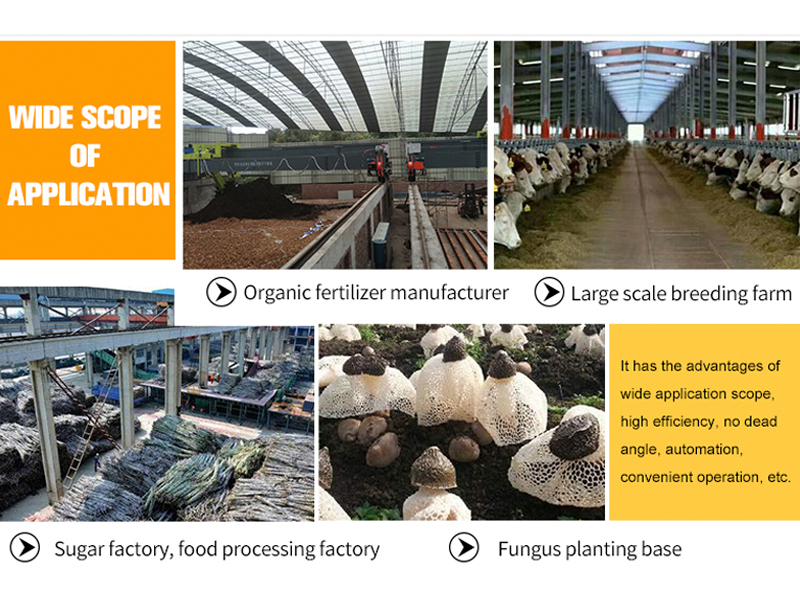

1. This machine is mainly used for particle processing in the (bio) organic fertilizer and aquaculture processing industries.

2. The granular material processed by this machine has a smooth surface and moderate hardness. During the processing, the temperature rise is low and the internal nutrients of the raw material are well maintained.

Suitable users and characteristics of non drying organic fertilizer production line equipment:

1. This machine is mainly used for particle processing in the (bio) organic fertilizer and aquaculture processing industries

2. The granular material processed by this machine has a smooth surface and moderate hardness. During the processing, the temperature rise is low and the internal nutrients of the raw material are well maintained

3. The particle composition is uniform and the shape is neat. The pore size of the particles can be divided into: Φ 2, Φ 2, Φ 3.5, Φ 4, Φ 5, Φ 6, Φ 7, Φ 8, etc.

4. Due to the low moisture content of particles, they are easy to store and can maintain their original state in water for a long time, greatly improving the utilization rate of materials.

Precautions for Non drying Organic Fertilizer Production Line Equipment:

1. When using, attention should be paid to the absence of hard objects such as stones and iron blocks in the raw materials. After working for more than ten shifts (8 hours per shift), high-temperature resistant grease should be added to the bearings of the rollers to improve their working performance and extend their service life;

2. If the particles are crushed or compressed improperly, the formula for coarse fiber materials should be reduced to less than 50%;

3. If there is no granulation or discharge during granulation, the membrane plate should be removed, and after opening each hole, some fiber materials should be added appropriately to restart granulation;

4. The gearbox should be checked regularly for oil leakage and the oil seal should be replaced in a timely manner.

see details +

see details +

see details +

see details +

Fermentation Compost Equipment >

Tel:+86 18538527111

Tel:+86 18538527111

E-mail:[email protected]

E-mail:[email protected]

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Privacy Policy Copyright © Henan Tongda Heavy Industry Science And Technology Co., Ltd.