Product Description

Product introduction

Pig manure organic fertilizer production line is a series of production equipment, which is made of pig manure by fermentation and processing of high-tech equipment.

Performance characteristics

1. Pig manure organic manure has a kind of biological and enzymes, which can enhance the biological and enzymatic activities of the land, increase the nutrient content of the soil, and improve the acidity and alkalinity of the soil, so that the soil can be suitable for the growth of various farming.

2. Organic fertilizer produced by pig manure organic fertilizer production line is nutritious. If it is put evenly, no additional fertilizer is needed for at least 100 days. This effect can not be replaced by any fertilizer.

3. Pig manure organic manure production line can add pesticides to reduce diseases and pests.

4. Organic fertilizer produced by pig manure organic fertilizer granulator is nutritious. If it is put evenly, no additional fertilizer is needed for at least 100 days. This effect can not be replaced by any fertilizer.

5. Organic fertilizer produced by pig manure organic fertilizer production line has comprehensive nutrition, and besides nitrogen, phosphorus and potassium, it also contains abundant calcium, magnesium and silicon, which can change soil composition and benefit crop growth.

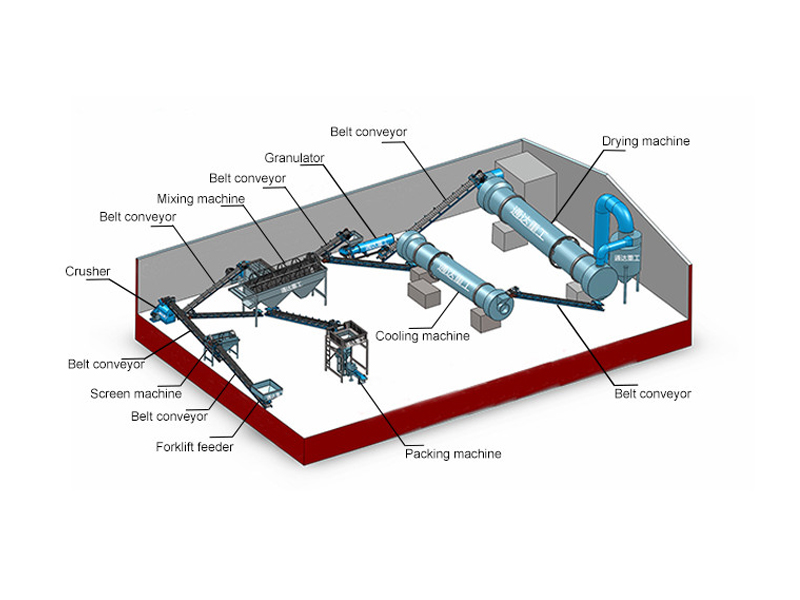

Working principle

1. Fermentation of raw materials.

2. Fully automatic weighing system.

3. Crushing and mixing.

4. Disc granulation, drum granulation, extrusion granulation.

5. Dryer drying organic fertilizer particles.

6. Cooler organic fertilizer particles.

7. Sieving machine Screening qualified organic fertilizer particles - Intelligent small-scale fertilizer distribution equipment - intelligent small-scale organic fertilizer production line.

8. Coating machine film particles, smoother.

9. Package automatic filling of organic fertilizer particles by loading scale.

Technical parameter

1. Fermentation of raw materials: chicken manure, pig manure, cow manure, biogas residue and other animal manure can be fermented or processed with fertilizer-efficient raw materials in a certain proportion (according to market demand and soil test results in different places).

2. Material mixing: mixing the raw materials evenly to improve the uniform fertilizer efficiency of the whole fertilizer granule.

3. Material granulation: Feed the uniformly stirred material into the granulator for granulation (drum granulator or extrusion granulator can be used).

4. Particle drying: The granulator is fed into the dryer, and the moisture contained in the granule is dried to increase the strength of the granule and to facilitate its preservation.

5. Particle cooling: After drying, the temperature of fertilizer particles is too high and easy to agglomerate. After cooling, it is easy to store and transport in bags.

6. Particle Classification: After cooling, the particles are classified. The unqualified particles are crushed and re-granulated, and the qualified products are screened out.

7. Finished product coating: coating qualified products to increase the brightness and roundness of particles.

8. Packaging of finished products: Film-coated particles, i.e. finished products, are packed and stored in a ventilated place.

Mobile/Whatsapp

Mobile/Whatsapp E-Mail

E-Mail

Get Price

Get Price Send E-mail

Send E-mail

Tel:

Tel: E-mail:

E-mail: Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.