Product Description

Product introduction

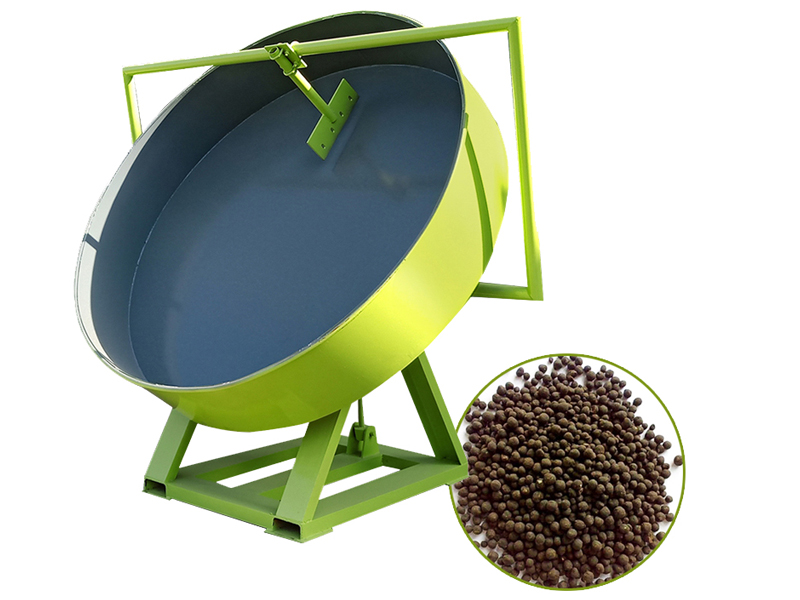

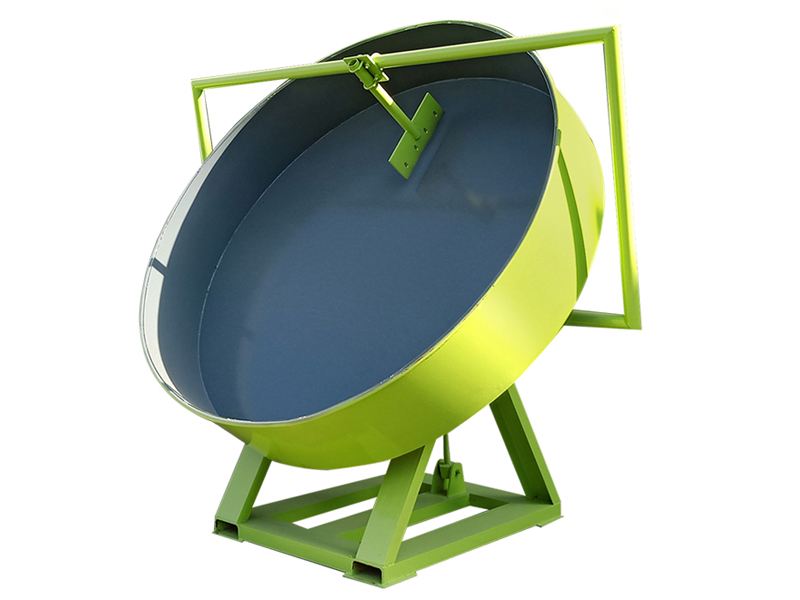

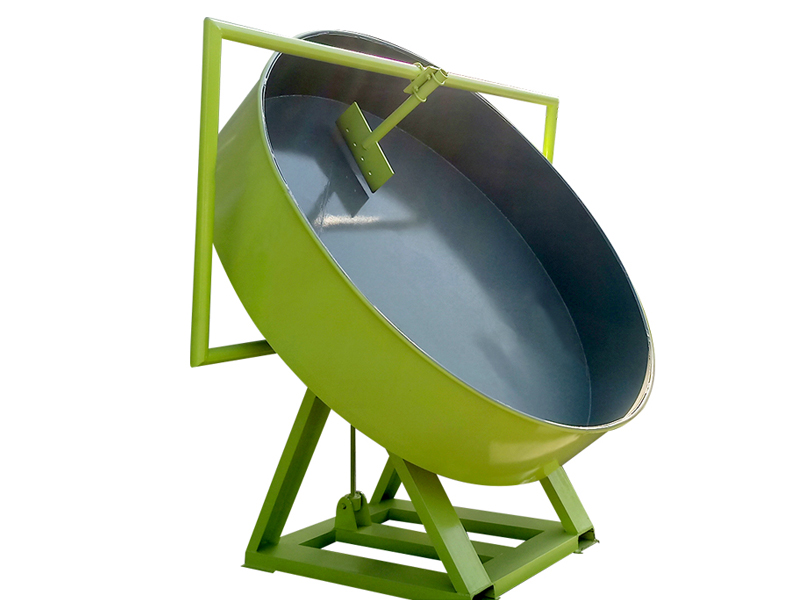

Disc granulator (also known as the ball plate) adopts the whole circular arc structure, and the granulating rate can reach more than 93%. It has three discharging ports, which is convenient for discontinuous production, greatly reducing the labor intensity and improving the labor efficiency. The reducer and motor use flexible belt drive to start smoothly, slow down the impact force and improve the service life of the equipment. The plate bottom is strengthened by a plurality of radiant steel plates, which is durable and never deformed. It is an ideal equipment for organic fertilizer and compound fertilizer, which is designed with thick, heavy and strong base, so it has no fixed anchor bolts and smooth operation.

Performance characteristics

1.High efficiency.The circular granulation machine adopts the whole circular arc structure, the granulation rate can reach more than 93%.

2.Long service life.

3.The bottom of granulation plate is strengthened by a number of radiation steel plates, which are durable and never deformed.

4.Granulator plate lined with high strength glass steel, anti-corrosion and durable.

5.The raw materials have wide applicability. It can be used for the granulation of various raw material, like compound fertilizer, medicine, chemical industry, feed, coal, metallurgy.

6.Reliable operation and low cost. The machine’s power is small, and operation is reliable; it has no three waste discharge, the operation is stable, and the maintenance is convenient.

Working principle

The raw material powder is evenly stirred by pre-adding water, and input into the dish. As the dish rotates, the material gradually forms into a ball in the body of the dish by rolling, and reaches the predetermined diameter before being out of the dish, and then transported to the next process.

Mobile/Whatsapp

Mobile/Whatsapp E-Mail

E-Mail

Get Price

Get Price Send E-mail

Send E-mail

Tel:

Tel: E-mail:

E-mail: Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.