Update time : 2021-09-01 Publisher:Tongda

Cow manure organic fertilizer raw materials:

Before composting, the raw materials of cow dung should be pretreated to meet the fermentation conditions such as water content, carbon nitrogen ratio and so on. Generally, the carbon nitrogen ratio of cow dung raw material is 19-23:1, which is basically suitable for composting requirements, but the water status of cow dung is very different. The water content of cow dung in large-scale farms is as high as 60% - 80%. Measures must be taken to reduce the water content to 50% - 60% before composting. It is recommended to reduce the water content of cow dung by recycling and mixing, that is, add fermented low water cow dung materials (about 30%) to the high water cow dung pile. After mixing the two dry and wet materials, the water content of the overall composting raw materials can be effectively reduced. The advantages of this pretreatment method are easy access to raw materials and low treatment cost. If the moisture content of fresh cow dung is more than 80%, the method of solid-liquid separation of cow dung can also be used to reduce the moisture content.

Cow dung composting fermentation:

There are two main processes for aerobic composting of cow dung:

1. Strip stack composting process: the materials with appropriate moisture adjustment are paved into strip stacks in layers according to the height and width. The strip stacks are arranged in parallel on the open-air or indoor flat composting yard, and the professional stacker is used to ride across the material stack for continuous stacking operation. The section shape of the stockpile is triangular or trapezoidal: 1.5-2.5m wide, 0.8-1.4m high and 50-150m long (depending on the shape and size of the composting site). The characteristics of the process: the mechanical turning operation has strong mobility, and the use of strip stacking is conducive to the loss of water in the later stage of composting; It has low requirements for civil engineering, does not need supporting fermentation tank, and can be stacked outdoors to save construction investment; The area of composting site needs to be relatively large; Outdoor composting in northern China has poor thermal insulation in winter, so the composting cycle needs to be prolonged or stopped seasonally; When composting in the open air, the material pile is easy to be affected in the rainy season. It is recommended to cover the canopy conditionally.

2. Solar fermentation tank composting process: materials with appropriate moisture adjustment are laid in the fermentation tank of solar composting workshop through distributor truck or forklift. The suitable height, width and length of the fermentation tank are 1.0-1.3m, 6m and 50-100m, which can be determined by referring to the floor area of the cattle farm and the shape of the plot. The process has the following characteristics: it can realize the continuous fermentation process of feeding at one end and discharging at the other end of the fermentation tank, and can also realize the full tank batch fermentation process; Adopt forced mechanical throwing for oxygenation and pipeline ventilation for oxygenation and aeration; The solar composting workshop has good temperature rise, thermal insulation effect and regulation function, and can carry out composting production all year round. Considering the material characteristics of cow dung, in order to save investment, canopy can also be used to replace solar composting workshop in southern China.

According to the water content of cow dung raw materials, one of the above composting processes can be selected or the two composting processes can be combined for composting. For example, the cow dung is first composted at high temperature through trough composting. After harmless, the materials are removed from the fermentation tank to the strip pile composting yard for secondary fermentation and further reduce the water content, so as to promote the further humification and mineralization of organic nutrients, and then mature. The investment in the combined equipment of the two processes increased slightly, but the composting efficiency and quality were improved.

Organic fertilizer products can be made into granules or powders, depending on market demand. In order to balance nutrients and be suitable for transportation and storage, it is recommended to process organic-inorganic compound fertilizer into granular products with cylindrical and spherical shapes. The moisture content of finished particles shall be: organic fertilizer ≤ 20%; Organic inorganic compound fertilizer ≤ 10%.

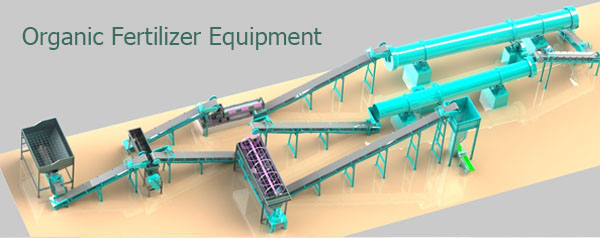

The fertilizer making process of organic fertilizer mainly includes crushing, batching, mixing, granulation, drying, cooling, screening and packaging. The equipment production capacity of a single production line should be 1 ~ 10t / h. if it is too small, it will not reach the economic scale, and if it is too large, it will increase the difficulty of transportation and storage of raw materials and finished products

see details +

see details +

see details +

see details +

Fermentation Compost Equipment >

Tel:+86 18538527111

Tel:+86 18538527111

E-mail:[email protected]

E-mail:[email protected]

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Privacy Policy Copyright © Henan Tongda Heavy Industry Science And Technology Co., Ltd.