Update time : 2021-11-04 Publisher:Tongda

Every year, tens of thousands of tons of dried Chinese herbal medicines are used in the production, and the extracted Chinese herbal residues account for more than 80% of the total extract. However, a large amount of residual Chinese medicine residues are almost dumped into the garbage, which wastes resources, pollutes the environment and occupies a large area of land.

Most of the organic matter of Chinese medicine residue is in line with organic fertilizer production, so any Chinese medicine residue can be used as raw material for organic fertilizer production and turn waste into treasure.

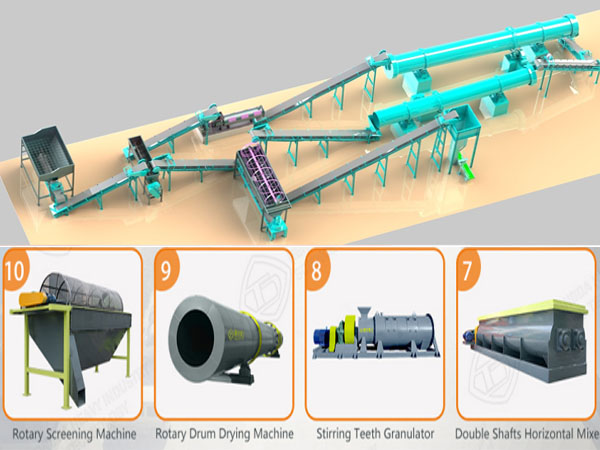

How to use pharmaceutical residue to produce organic fertilizer? The methods, steps and equipment required for the production of pesticide residue and organic fertilizer are as follows:

1. raw material crushing: the production of pharmaceutical residue, through the crusher crushed 10 ~ 50 mesh, crushing purpose is to avoid the fermentation tank in the process of ripening and stirring swirling leaves;

2. Ingredients: Put the crushed pharmaceutical residues, livestock and poultry excrement, fermentation bacteria and water in the blender according to 55-70:15 ~ 25:2 ~ 4:10 ~ 30 and stir evenly;

3. high temperature equipment fermentation: put the mixed materials in step 2 into high temperature fermenter, keep the temperature of 60 ~ 90℃, fermentation can be completed in 1~2 days;

4. Aging: Place the materials fermented in step 3 in the aging chamber, keep the temperature at 60 ~ 70℃ under ventilation, and carry out secondary fermentation during aging for 3 ~ 6 days;

4. Aging: Place the materials fermented in step 3 in the aging chamber, keep the temperature at 60 ~ 70℃ under ventilation, and carry out secondary fermentation during aging for 3 ~ 6 days;

5. Granulation: step 5 pharmaceutical residue and other raw materials, crushed again into the granulation machine, at the temperature of 50 ~ 60℃, maintain material moisture 8 ~ 15%, granulation;

6. Drying: in the dryer, keep ventilation, control the temperature of 100 ~ 120℃, drying 20 ~ 40min, material moisture 3 ~ 5%;

7. Cooling: Put the materials dried in step 7 into the cooling machine and cool to room temperature under ventilation;

8. Finished product: The cooled material in Step 8 is screened by a screening machine, with the particle size remaining 1 ~ 4.5mm, and packaged.

How much is the production line of organic fertilizer of complete residue? There is no complete answer to this problem, because different equipment configuration schemes, different production line process design, different production demand, need to spend money will have a certain difference, the specific equipment quotation depends on the actual configuration. However, it is certain that the configuration is more scientific, more reasonable and more suitable for actual production. The price investment of the equipment will be more cost-effective. The price investment of the general full set of pharmaceutical residue organic fertilizer production line will be in the range of hundreds of thousands to millions.

see details +

see details +

see details +

see details +

Fermentation Compost Equipment >

Tel:+86 18538527111

Tel:+86 18538527111

E-mail:[email protected]

E-mail:[email protected]

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Privacy Policy Copyright © Henan Tongda Heavy Industry Science And Technology Co., Ltd.