Update time : 2021-07-09 Publisher:Tongda

Pig manure organic fertilizer production line:

1. According to the local actual situation, this project makes full use of the livestock and poultry manure resources from the surrounding farms of the company, introduces advanced domestic production technology, uses live bacterin to ferment the livestock and poultry manure and other materials, and processes them into pollution-free and nutrient-rich biological organic fertilizer.

Reduce the local livestock and poultry manure pollution to the environment, to achieve obvious economic, social and ecological benefits.

2, treatment technology: raw material pretreatment mainly includes auxiliary materials crushing, fermentation raw materials loading tank and mixing operations. Straw and other auxiliary materials are crushed to 3-5mm long. The processing area of the factory and the auxiliary materials are laid in layers, with a thickness of 20cm each. From the inside to the outside, the mixing is carried out evenly by the tipping machine.

Fermentation agent is mixed into the fermentation tank when evenly turning. Aeration device is added in the fermentation tank to reduce the fermentation time. Dust collection cover is added in the upper part of the workshop to concentrate on the treatment of dust and odor.

3, after treatment: product quality standards

Moisture (travel ion) content (%) less than or equal to 20

Ph 5.5-8

The egg mortality rate is greater than or equal to 95%

The fecal coliform population is less than or equal to 0.1-0.01

(No odor, moisture from wet to dry)

1-100000 tons of biological organic fertilizer equipment production line 1-100000 tons of livestock and poultry manure resource utilization complete set of equipment 1-100000 tons of compound fertilizer equipment complete set of production line

1-100000 tons of non-dry extrusion granulation production line 1-100000 tons of BB fertilizer complete sets of equipment and spare parts, etc.

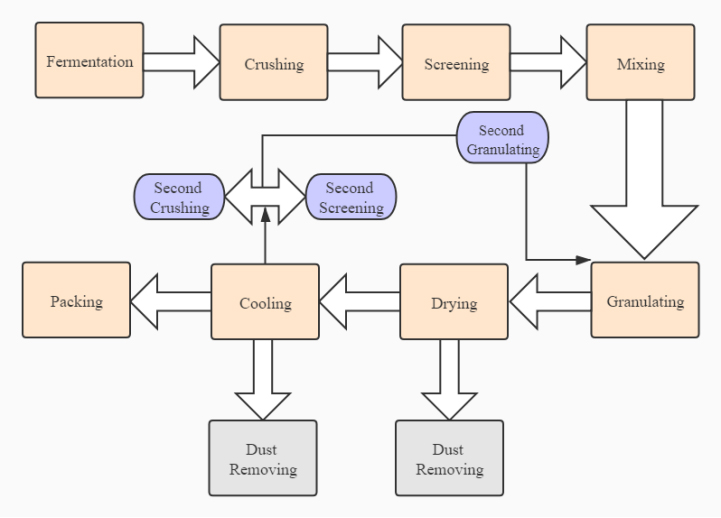

Production process of organic fertilizer:

The organic fertilizer production process of this project is as follows:

Fermentation: the livestock manure (dry manure) is transported to the fermentation tank through the transport vehicle, and the raw materials such as humic acid, chelating agent and amino acid are put into the fermentation tank in a certain proportion. At the same time, biological strains are added to convert the animal manure into organic fertilizer components.

This project mainly uses pig manure, cow manure and sheep manure as raw materials, ferments by high temperature aerobic composting technology, and then goes through post-ripening treatment, and finally is processed and granulated to produce highly efficient and green refined organic manure. The main production technology of organic fertilizer in this project

Including raw material pretreatment, composting, secondary fermentation, screening, granulation, cooling, packaging and other processes, as shown in Fig. 5-1. Among them, powdery organic fertilizer without granulation process, directly into powdery products.

The preliminary raw materials are premixed after fermentation treatment. When premixed according to the production of organic fertilizer formula, add a certain amount of N/PK and trace elements.

Three raw material pretreatment:

The pretreatment of raw materials mainly includes the crushing of auxiliary materials, the charging and mixing of fermentation raw materials. Stalks and other auxiliary materials were crushed to 3-5cm long. The pig manure in the factory is transported to the pretreatment area by pipeline from the pig house. (The pig manure outside the production area needs to be fermented with bacteria.

After sterilization, the pig manure and auxiliary materials are laid in layers with a thickness of 20cm each. From the inside to the outside, the pig manure is evenly mixed by the throwing machine. Fermentation bacteria are mixed when evenly turning.

Fermentation and decomposing process includes mixed composting fermentation and secondary decomposing fermentation. Mixed composting fermentation refers to aerobic fermentation and decomposing of mixed materials through tank aerobic fermentation system. The bottom of the fermentation tank is equipped with a ventilation system for compulsory use

Ventilation and oxygen supply, turn the material evenly with a thrower, turn the material every 3-5 days, aerobic fermentation cycle is 30 days. After the aerobic fermentation, the fermentation materials will be transported to the secondary decomposing workshop. The secondary decomposing refers to the aerobic fermentation in the form of strip stacker

The product is rotated twice to reach the standard of organic fertilizer. The material is evenly rotated with a thrower. The rotated material is rotated once every 5-7 days, and the second rotated period is 15 days.

After the secondary decomposition of the material, the production of powdered organic fertilizer by adding biological agents, mixing, cooling and screening, packaging and storage of the same steps, the production of powdered organic fertilizer.

After the secondary decay of the material, the production of granular refined organic fertilizer in turn for batching, mixing, granulation, cooling screening, packaging and storage steps, the production of granular refined organic fertilizer.

see details +

see details +

see details +

see details +

Fermentation Compost Equipment >

Tel:+86 18538527111

Tel:+86 18538527111

E-mail:[email protected]

E-mail:[email protected]

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Privacy Policy Copyright © Henan Tongda Heavy Industry Science And Technology Co., Ltd.