Update time : 2021-08-23 Publisher:Tongda

Refined products are needed to improve the quality of livestock manure organic fertilizer. After secondary fermentation, impurities such as glass, ceramics, plastics, wood chips, fibers and stones must be removed. The purified bulk organic fertilizer products can be directly sold to users for application in farmland, vegetable garden, orchard or as soil conditioner. According to soil conditions and user needs, nitrogen, phosphorus and potassium can be added into bulk organic fertilizer to make organic fertilizer inorganic compound fertilizer and bagged, This is convenient for transportation and storage, and has better fertilizer efficiency.

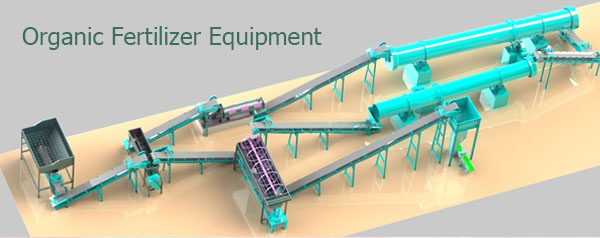

The post-treatment equipment includes sorting, grinding, granulation, bagging and other equipment. In the actual process, the combined post-treatment equipment shall be selected according to the local needs.

(1) The reason why the sorting equipment for post-treatment of sorting equipment is different from pretreatment is that the particle size range of compost after pretreatment and secondary fermentation is far smaller than that of pretreated materials. Therefore, post sorting equipment is more exquisite than pre sorting equipment, and the means adopted are different. Post sorting equipment mostly adopts relaxation screen, elastic sorter, electrostatic sorter, etc.

(2) Granulation refining equipment granulation refining equipment is used for granulation of organic fermentation materials, which is conducive to storage and transportation, so as to meet the change of seasonal demand for organic fertilizer. The granulator must have the ability to process a certain size particle size ratio and a certain amount of organic fertilizer. The particle size ratio refers to the ratio of uncompressed particle size volume of organic fertilizer to compressed particle size volume, which can be measured through screening. Disc granulation or extrusion granulation is usually used for granulation. The forming mechanism of the granulator is related to the following factors, which should be paid full attention to when using the equipment in order to obtain the ideal effect: ① humidity is related to the formation of water surface tension or capillary action; ② The particle composition is related to the material injected into the granulator; ③ The particle shape is related to the adhesion of the material injected into the granulator; ④ The surface density is related to the pressure ratio.

(3) Considering the convenience of transportation, management and storage, the packer is often used to pack the final organic fertilizer products. The material, size and shape of the packaging bag and the specification of the packaging machine should be selected according to the quantity and purpose of organic fertilizer.

see details +

see details +

see details +

see details +

Fermentation Compost Equipment >

Tel:+86 18538527111

Tel:+86 18538527111

E-mail:[email protected]

E-mail:[email protected]

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Address:Longgang Development Zone Of Xingyang City, Zhengzhou City, Henan Province, China.

Privacy Policy Copyright © Henan Tongda Heavy Industry Science And Technology Co., Ltd.